Aluminum coil are widely used in stamping, home appliance industry, sheet metal production, decoration curtain wall, automotive industry, mold processing, ship manufacturing, transportation facilities, pipeline insulation, lighting lamps, advertising signs, etc. The characteristics of aluminum are good corrosion resistance, sufficient strength, excellent process performance and welding performance.

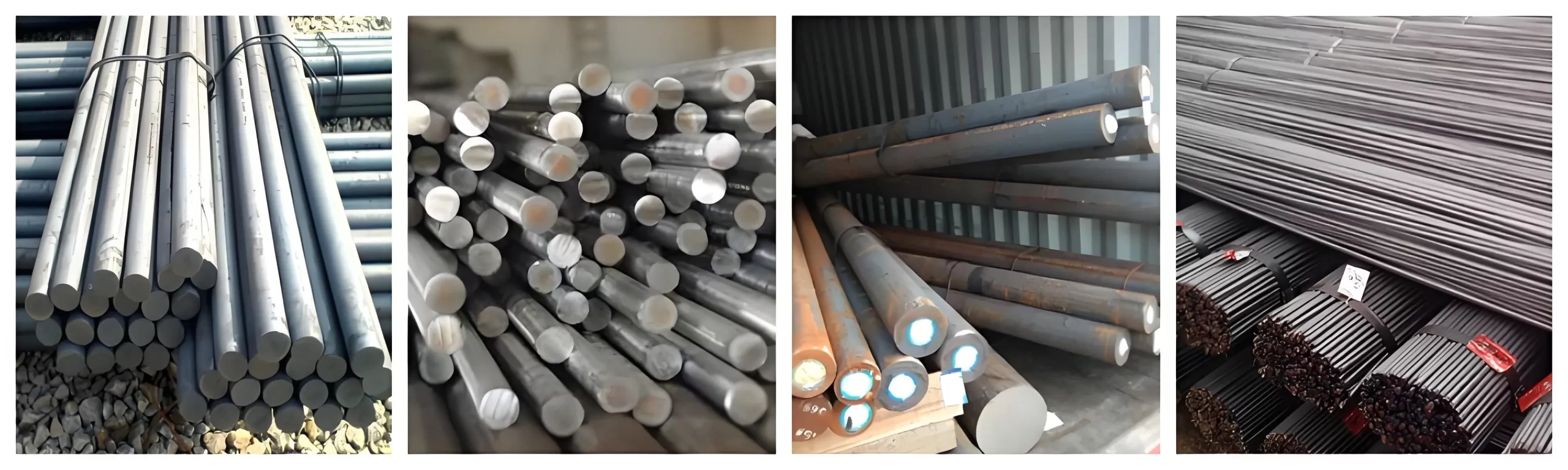

Category: Carbon steel rod

Key word: Carbon steel rod

![]() Whatsapp :+86 15563533366

Whatsapp :+86 15563533366

![]() Email : admin@sdxtdsteel.com

Email : admin@sdxtdsteel.com

used for manufacturing all kinds of mechanical parts, such as shafts, pins, connecting rods, etc.

used as reinforcing ribs or supporting parts in building structures.

is a commonly used material in the production of molds.

such as hammers, wrenches and other tools are made.

used for parts of automobile engines.

manufacturing parts of drilling pipes and other mining equipment.

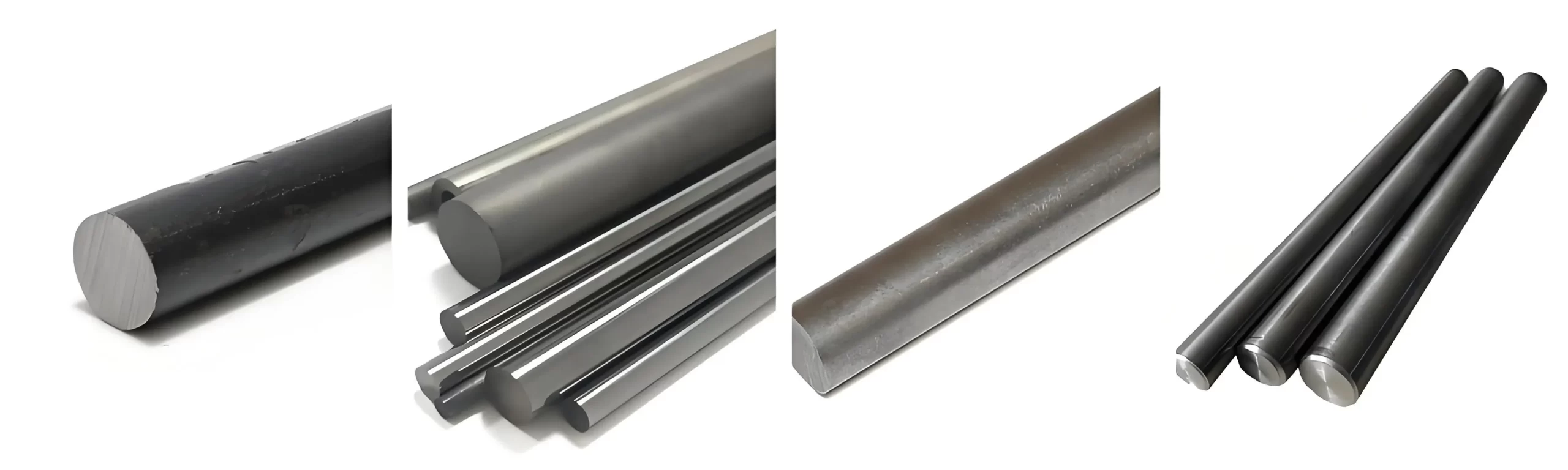

| Item | Carbon Steel Bars |

|---|---|

| Standard | GB/T 700-2006, GB/T 1591-94, JIS G3101-2004, ASTM A36/A36M-05, ASTM A242/A242M-04, ASTM A529/A529M-05, ASTM A572/A572M-06 etc. |

| Material | Q195, Q215 A, Q215 B, Q235 A, Q235 B, Q235 C, Q235D, Q275, Q275B, Q275C, Q275D, Q295, Q345, Q390, Q420, Q460, SS330, SS400, SS490 etc. |

| Diameter | 4mm~800mm |

| Length | 1m, 3m, 5.8m, 6m, 12m or as required |

| Surface | Polished, bright, black, coated |

| Package | Standard export seaworthy or as customers’ requirements |

| Export | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Iraq, Russia, Holland, Turkey, Kuwait, |

| Price terms | EXW, FOB, CFR, CIF |

| Payment terms | T/T., LC at Sight, LC at 90 Days, D/P, O/A |

| Delivery time | 7-10 days, upon the final quantity you demand |

1. The density is relatively large, generally around 7.8 g/cm3. 2. Strength and hardness depend on its carbon content. The higher the carbon content, the greater the strength and hardness. 3. Has a certain toughness and ductility, but not as good as pure iron. 4. Good thermal and electrical conductivity.

1. Relatively stable in a dry environment at room temperature. 2. Oxidation reaction easily occurs in a humid and oxygen-rich environment, resulting in rust. 3. Can react with dilute hydrochloric acid, dilute sulfuric acid and other acids to generate hydrogen and corresponding salts. 4. Easily react violently with oxygen at high temperatures.

Channel steel dimension

H steel dimension

Angle steel dimension

Channel steel dimension

Steel rebar dimension

H steel dimension

Angle steel dimension