Carbon steel, refers to iron-carbon alloys with carbon content below 2% and 11%. Carbon steel is divided into carbon structural steel, carbon tool steel and free-cutting structural steel. Carbon structural steel is divided into engineering construction steel and mechanical manufacturing structural steel; according to the smelting method, it can be divided into open hearth steel and converter steel; according to the deoxidation method, it can be divided into boiling steel (f), killed steel (z), semi-killed steel (b) ) and special killed steel (TZ); (4) According to the carbon content, carbon steel can be divided into low carbon steel (WC≤0.25%), medium carbon steel (WC 0.25%-0.6%) and high carbon steel (WC> 0.6%).

Category: Carbon steel plate

Key word: Carbon steel plate

![]() Whatsapp :+86 15563533366

Whatsapp :+86 15563533366

![]() Email : admin@sdxtdsteel.com

Email : admin@sdxtdsteel.com

Low carbon steel plates are mainly used in construction, machinery manufacturing, container manufacturing, shipbuilding, bridge construction, some parts of tractors and welded components, etc. Medium carbon steel plates are widely used in the manufacture of various mechanical parts, such as axles, gears or building materials. High carbon Steel plates are mainly used to make smaller parts, iron wire, hoops, knives, high-strength wire and springs, etc.

Mainly include: pig iron, carbon structural steel, high-quality carbon structural steel, low-alloy structural steel, alloy structural steel, spring steel and bearing steel, tool steel, stainless steel and heat-resistant steel.

Widely used in construction, bridges, railways, vehicles, ships and various machinery manufacturing industries, and also widely used in modern petrochemical, marine development, etc.

| Product Name | Carbon Steel Plate | |||||||

|---|---|---|---|---|---|---|---|---|

| Grade | Shipbuilding steel plate:A32, AH32,A36,AH36,DH36,D32 DH32 etc. | |||||||

| High strength steel plate :Q460C/D/E, Q235B/C/D/E, Q345B/C/D/E, Q609C/D/E | ||||||||

| Alloy steel plate:40Cr,50Mn,65Mn,15CrMo,35Crmo,42CrMo etc | ||||||||

| Pressured vessel steel plate:Q245R,Q345R,Q370R etc | ||||||||

| Application | This kind of steel has a good resistance to abrasion, so it is widely used in engineering machinery, metallurgical machinery, coal industry, mining machinery,environmental protection machinery,the feeder,container,dumper bodies, sieve plate,hoister,edge plate,wheel gear,cutter etc other industry. | |||||||

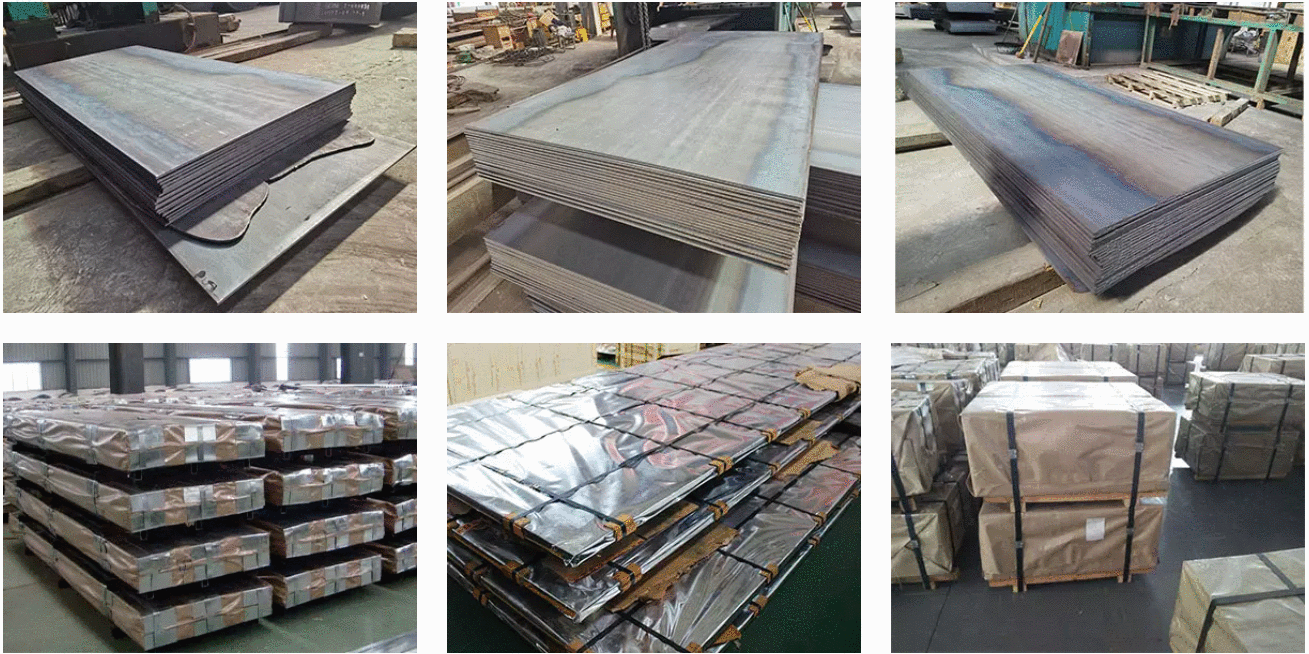

| Surface | natural color coated galvanized or customized | |||||||

| Standard | DIN GB JIS BA AISI ASTM EN etc | |||||||

| Certificate | ISO SGS | |||||||

| Technique | hot rolled or cold rolled | |||||||

| Thickness | 0.12-200mm or as required | |||||||

| Width | 1500-2000mm or as required | |||||||

| Length | 6000-12000mm or as required | |||||||

Channel steel dimension

H steel dimension

Angle steel dimension

Channel steel dimension

Steel rebar dimension

H steel dimension

Angle steel dimension