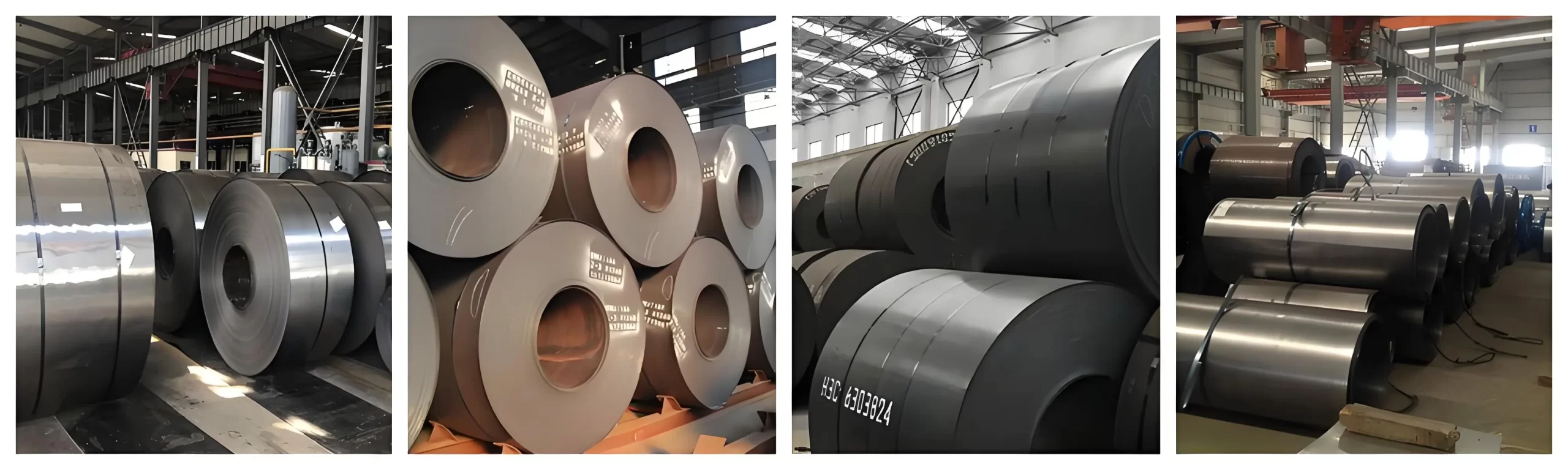

Carbon steel coil is a coil made of carbon steel as raw material. It has high density, strength and hardness vary with carbon content. It has moderate physical properties and is stable in dry environment. It is easy to rust when wet. Because of its moderate cost and diverse performance, it is widely used in construction, manufacturing, home appliances and other industries. It is a common and important material in industrial production.

Category: Carbon steel coil

Key word: Carbon steel coil

![]() Whatsapp :+86 15563533366

Whatsapp :+86 15563533366

![]() Email : admin@sdxtdsteel.com

Email : admin@sdxtdsteel.com

Used for manufacturing steel structural parts, such as steel beams, steel columns, etc.

Production of car body parts, mechanical parts, etc.

Manufacturing of enclosures and internal structural parts for refrigerators, washing machines, etc.

Processing into various pipes for conveying liquids and gases.

Construction of ship hull structures and equipment parts on ships.

| Cold Rolled/ Hot Rolled Ms Carbon Steel Coils | |||

|---|---|---|---|

| Thickness | Hot Rolled Thickness:2.75mm-100mm, as Your RequestCold Rolled Thickness:0.2mm-3mm, as Your Request | ||

| Width | 1250-2500mm,or as Your Request ( regular width 1000mm, 1250mm, 1500mm ) | ||

| Coil ID | 508mm or 610mm | ||

| Coil Weight | 3 – 8 ton or as Your Request | ||

| Standard | ASTM EN DIN GB ISO JIS BA ANSI | ||

| Steel Grade | Q195, Q215,Q235,Q345,ST37, A36,45# ,16Mn, SPHC,SGCC,CGCC | ||

| Technique | Hot rolled cold rolled as Your Request | ||

| Bare,Black,Oiled,Shot Blasted,Spray Paint,Coated,Galvanized,or as Your Request | |||

| Applies to appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. | |||

| Standard Export packing. | |||

| Payment Term | Pay 30%T/T deposit in advance, 70%T/T the balance before shipment.under $10,000, pay in full by T/T. | ||

| Remarks | Insurance per to Contract terms;MTC will be handed on with shipping documents;We accept the third party certificatation test. | ||

Physical and chemical properties

Physical and chemical properties1. High density, usually around 7.85 g/cm3. 2. Strength and hardness vary depending on the carbon content. The higher the carbon content, the greater the strength and hardness. 3. Thermal and electrical conductivity are average. 4. Has a certain toughness and ductility, but is relatively limited.

1. It is more stable in a dry environment at room temperature. 2. It is easy to rust in a humid and aerobic environment, and an oxidation reaction occurs. 3. It can chemically react with acid. The degree of reaction depends on the type and concentration of acid and the carbon content of carbon steel. 4. It is easy to react with gases such as oxygen and carbon dioxide at high temperatures.

Channel steel dimension

H steel dimension

Angle steel dimension

Channel steel dimension

Steel rebar dimension

H steel dimension

Angle steel dimension