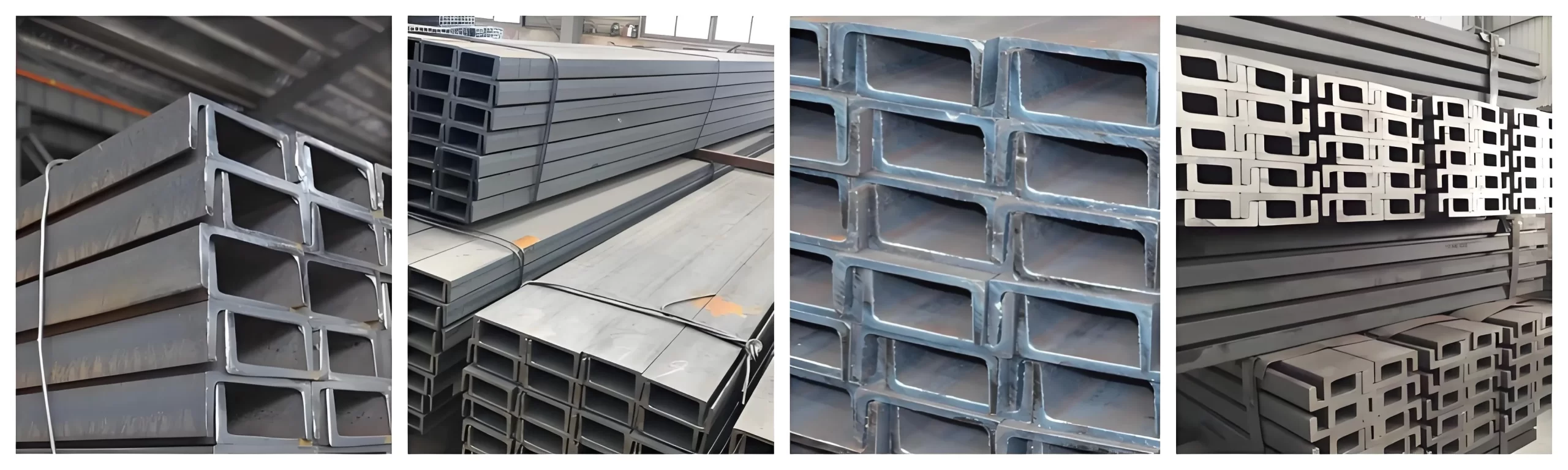

Carbon steel channel steel is a commonly used steel profile. Made of carbon steel, it has high density and high strength. Its unique shape and good bearing capacity. Widely used in construction, machinery and other fields, as a structural support component, economical and practical, is one of the indispensable basic materials in industrial production and construction.

Category: Carbon steel channel steel

Key word: Carbon steel channel steel

![]() Whatsapp :+86 15563533366

Whatsapp :+86 15563533366

![]() Email : admin@sdxtdsteel.com

Email : admin@sdxtdsteel.com

used for the construction of beams, columns, and other frame structures.

as a support and frame component for various types of machinery and equipment.

It is an important component of the bridge structure.

used for the structural framework of ships.

the main materials for building warehouse shelves.

Constructing the structural components of a power transmission tower.

| Length | 6m, 9m, 12m or as required |

|---|---|

| Thickness | 1.0mm-6.0mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled |

| Surface Treatment | Clean, blasting and painting according to customer requirement |

| Thickness tolerance | ±0.1mm |

| Material | Q345B,Q345C,Q345D,Q345E,Q390,Q390B,Q390C,Q390D,Q390E,Q420, Q420B,Q420C,Q420DQ420E,Q460,Q460D,Q500C,Q500D,Q500E,Q550C, Q550D,Q550E,Q620C,Q620D,Q620E,Q690A,Q690B,Q690C,Q690D, Q690E,Q690D,Q690C,Q890C,Q890D |

| 16Mo3,16MnL,16MnR ,16Mng,16MnDR | |

| HG785D,S690QL,50MN | |

| Application | It is mainly used to make structural parts such as car girder, beam, transmission shaft and car chassis parts, which can reduce the weight of the parts. |

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed. |

| Standard Export Seaworthy Package.Suit for all kinds of transport,or as required | |

| Capacity | 250,000 tons/year |

Physical properties of carbon steel channel steel:

Physical properties of carbon steel channel steel:1. The density is about 7.85 g/cm3. 2. Strength and hardness depend on its carbon content and processing technology, usually with high strength. 3. Has a certain degree of ductility and toughness, can withstand a certain degree of deformation.

1. It is relatively stable in dry and normal temperature environments. 2. It is easy to rust and oxidize in humid and oxygen environments. 3. It can chemically react with acids to produce hydrogen and corresponding salts.

Channel steel dimension

H steel dimension

Angle steel dimension

Channel steel dimension

Steel rebar dimension

H steel dimension

Angle steel dimension